Pipe dope, a thick paste or gel, provides a strong, durable seal for high-pressure and temperature applications like gas lines and high-pressure water lines. On the other hand, Teflon tape, a thin, white tape, is easier to apply and remove, making it a convenient option for low-pressure water lines and temporary connections.

We have summarized the key differences between pipe dope and Teflon tape here:

| Feature | Pipe Dope | Teflon Tape |

|---|---|---|

| Material | Paste or gel | Thin, white tape |

| Application | High-pressure and high-temperature joints | Low-pressure joints |

| Ease of application | More difficult to apply | Easy to apply |

| Ease of removal | Easy to remove | Easy to remove |

| Permanence | More permanent | Less permanent |

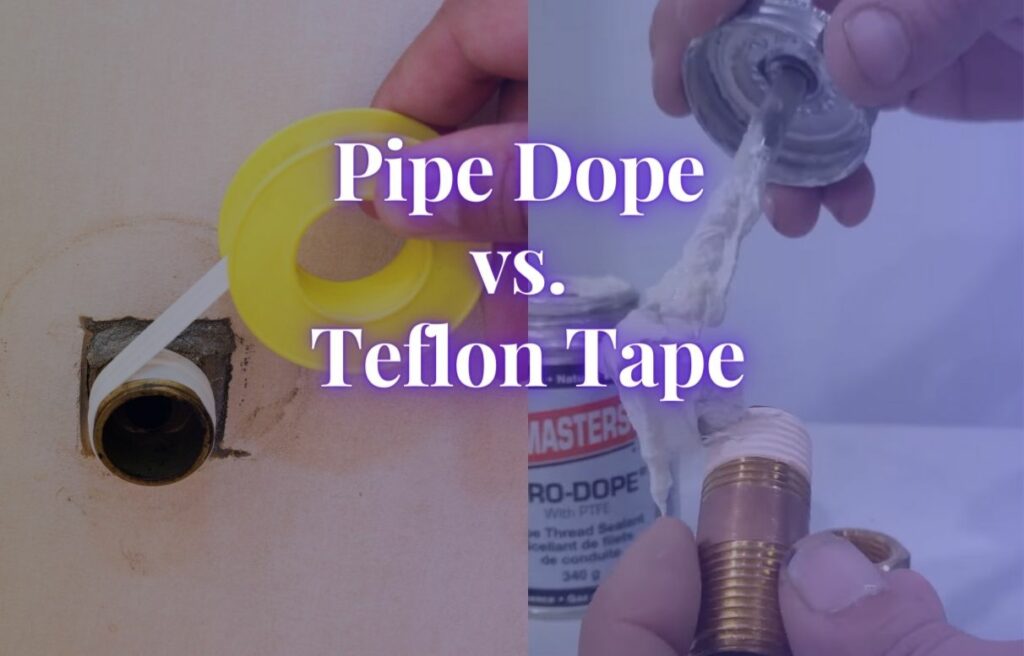

pipe dope Vs Teflon tape

Here’s a comprehensive overview of the key differences between pipe dope and Teflon tape:

Pipe Dope

Pipe dope, also known as pipe joint compound or thread sealant, is a thick, paste-like substance applied to the threads of a pipe before it is screwed into a fitting. It fills in the microscopic gaps between the threads, creating a durable seal that can withstand high pressure and temperature.

Pipe dope is often formulated with specific additives to enhance its properties, such as corrosion resistance or high-temperature tolerance.

Characteristics of pipe dope:

- High-pressure resistance: Pipe dope excels in sealing joints that experience high pressure, making it ideal for gas lines, water lines, and other pressurized systems.

- Temperature resistance: Pipe dope can withstand a wide range of temperatures, including extreme heat and cold, making it suitable for various plumbing applications.

- Durability: Pipe dope forms a strong, long-lasting seal that can endure years of use.

Teflon Tape

Teflon tape, also known as thread seal tape or plumber’s tape, is a thin, white tape made of polytetrafluoroethylene (PTFE). It is wrapped around the threads of a pipe before it is screwed into a fitting.

Teflon tape conforms to the threads, filling in any gaps and creating a seal that can withstand low-pressure applications.

Characteristics of Teflon tape:

- Low-pressure applications: Teflon tape is primarily used for sealing low-pressure joints, such as household water lines.

- Ease of use: Teflon tape is easy to apply and remove, making it a convenient choice for DIY projects.

- Versatility: Teflon tape can be used with various pipe materials, including metal, plastic, and copper.

Durability and Permanence of Pipe Dope vs. Teflon Tape

Pipe Dope: Pipe dope makes a strong, long-lasting seal that can handle high pressure and heat. People use it for connections that won’t be taken apart often. If needed, you can remove pipe dope using special solvents or by carefully scraping it off.

Teflon Tape: Teflon tape is great for sealing connections with low pressure. It’s easy to remove – just unwind it from the threads. But remember, Teflon tape might not be the best choice for long-term, high-pressure situations.

The pros and cons of Pipe Dope

Well, now we are going to discuss about advantages and disadvantages of Pipe dope which is very crucial for this topic.

Pros of Pipe Dope:

- Strong and Durable Seal: Pipe dope creates a robust seal that can withstand high pressure and temperature, making it suitable for various plumbing applications, including gas lines, high-pressure water lines, and connections that may experience vibration or movement.

- Versatility: Pipe dope is compatible with various pipe materials, including metal, plastic, and PVC, making it a versatile choice for different plumbing systems.

- Easy Application and Removal: While the application requires careful coverage of threads, pipe dope can be easily removed with specialized solvents or by scraping, allowing for future adjustments or repairs.

- Lubrication: Pipe dope acts as a lubricant, facilitating smooth threading and reducing the risk of thread damage during installation or disassembly.

Cons of Pipe Dope:

- Messiness: Pipe dope’s thick, paste-like consistency can be messy to apply, requiring careful handling and clean-up.

- Potential for Clogging: If not applied properly, excess pipe dope can squeeze out and clog valves, filters, or other components downstream.

- Sensitivity to Solvents: Some pipe dope formulations may be affected by certain solvents or chemicals, potentially weakening the seal over time.

- Limited Adhesion to Certain Surfaces: Pipe dope may not adhere as effectively to certain materials, such as smooth or polished surfaces, requiring additional measures for a secure seal.

- Cure Time: Some pipe dope formulations require a curing time to fully harden, which may prolong installation or repair procedures.

The pros and cons of Teflon tape

Here are some of the pros and cons of using Teflon tape for sealing threaded pipe connections:

Pros of Teflon tape:

- Easy to apply: Teflon tape is very easy to apply. Simply wrap it around the threads of the pipe in the same direction as the threads. There is no need to use any tools or solvents.

- Can be removed easily: Teflon tape can be removed easily by simply unwinding it from the threads. This is a major advantage over pipe dope, which can be difficult to remove.

- Resistant to chemicals: Teflon tape is resistant to most chemicals, including solvents, oils, and gases. This makes it a good choice for sealing joints that are exposed to harsh environments.

- Non-toxic: Teflon tape is non-toxic and safe for drinking water applications.

- Low cost: Teflon tape is relatively inexpensive, making it a cost-effective solution for many sealing applications.

Cons of Teflon tape:

- Not as effective for high-pressure applications: Teflon tape is not as effective as pipe dope for sealing high-pressure joints. This is because Teflon tape is not as thick or as viscous as pipe dope, and it does not fill the gaps between the threads as completely.

- Can degrade over time: Teflon tape can degrade over time, especially if it is exposed to high temperatures or harsh chemicals. This can lead to leaks.

- Not suitable for all materials: Teflon tape is not suitable for all materials. For example, it should not be used on galvanized steel pipes, as it can react with the zinc coating and cause corrosion.

Comparing Suitable Applications:

Pipe Dope:

Pipe dope is the preferred choice for several applications, including:

- Gas lines: The high-temperature and pressure resistance of pipe dope makes it ideal for sealing gas lines.

- High-pressure water lines: Pipe dope can effectively seal water lines that carry high pressure, ensuring a leak-proof connection.

- Disassemblable joints: Pipe dope is a good choice for joints that may need to be disassembled in the future, as it can be removed without damaging the threads.

Teflon Tape:

Teflon tape is suitable for specific applications, such as:

- Low-pressure water lines: For low-pressure water lines, Teflon tape provides a simple and effective seal.

- Temporary connections: Teflon tape is often used for temporary plumbing repairs or connections that may be modified later.

- Plastic or non-metal pipes: Teflon tape is compatible with various materials, including plastic and non-metal pipes.

Pipe Dope vs. Teflon Tape for Gas Lines

When it comes to sealing gas lines, pipe dope is the preferred choice over Teflon tape due to its superior sealing capabilities and compatibility with gas applications. Pipe dope provides a thick, durable seal that can withstand the high pressure and temperature fluctuations common in gas lines. It also adheres well to metal pipes, which are the most common type of pipe used for gas distribution.

Reasons to Use Pipe Dope for Gas Lines:

- High-Pressure and Temperature Resistance: Pipe dope can withstand the high pressure and temperature fluctuations experienced in gas lines, preventing leaks and ensuring safety.

- Compatibility with Gas: Pipe dope is specifically formulated to be compatible with gas applications and will not react with or degrade the gas lines.

- Superior Sealing: Pipe dope creates a thick, durable seal that fills the gaps between threads, preventing gas leaks.

Why Teflon Tape is Not Recommended for Gas Lines?

Teflon tape is okay for a quick fix on low-pressure gas lines, but it’s not the best for long-term or high-pressure situations. It might not seal well, and it could wear out over time.

Is Teflon Tape Safe to Use on Gas Lines or Should I Use Pipe Dope Instead?

Teflon tape is safe to use on gas lines, but many professionals prefer to use pipe dope on gas lines instead. Pipe dope provides a better seal and is more resistant to the harsh chemicals found in natural gas. It’s essential to use pipe dope on gas lines to ensure a secure and long-lasting connection.

Pipe Dope vs. Teflon Tape for Water Lines

For both low-pressure and high-pressure water lines, pipe dope is generally considered a more reliable and durable sealant compared to Teflon tape. Pipe dope provides a thicker, more resilient seal that can withstand the pressure and temperature fluctuations encountered in water lines.

Reasons to Use Pipe Dope for Water Lines:

- High-Pressure and Temperature Resistance: Pipe dope can handle the pressure and temperature fluctuations experienced in water lines, preventing leaks.

- Durability and Longevity: Pipe dope forms a durable seal that resists degradation over time, ensuring long-lasting leak protection.

- Suitable for Various Materials: Pipe dope is compatible with various pipe materials, including copper, brass, plastic, and PVC.

Teflon Tape for Low-Pressure Water Lines:

Teflon tape can be a suitable option for sealing low-pressure water lines, particularly in DIY applications. It offers ease of application and removal, making it convenient for temporary or non-critical connections.

Considerations for Using Teflon Tape:

- Low-Pressure Applications: Teflon tape is best suited for low-pressure water lines to ensure adequate sealing.

- Temporary Connections: Teflon tape is ideal for temporary connections or those that may need future adjustments.

- Compatible Materials: Ensure Teflon tape is compatible with the pipe material, avoiding galvanized steel pipes.

Related: Pipe Dope Vs Plumbers Putty

Leave a Reply